Servo Type Automatic L Sealer

TY-7315

TY-7315 Machine Feature:

- Servo Motor control: Infeed belt, outfeed belt & film pulling.

- Sealing jaw opening height adjustable.

- Motor with soft start function for nice product sealing.

- Adjustable operation speed.

- Auto Film collection with sensor controlled.

- Efficient package capacity with close filling mode(non space between each product).

- Apply Mitsubishi PLC controller for stable operation performance.

- Apply Omron timer for control sealing & cutting time.

- Individual pin roller, adjustable pin position & amount.

- Adjustable film feeding tension.

- Panasonic sensors to control product entry position.

- Cutting blade made by 1 piece with long time operation durability.

- Temp. controller with PID function and driven by SSR for stable heating performance.

- Auto abnormal warning on sealing & cutting set.

- Infeed conveyor apply with roller for smooth operation.

- Directly adjustment on product entry width without hand tool.

- Rubber roller for tight film holding and pulling by timing belt.

- CE model available.

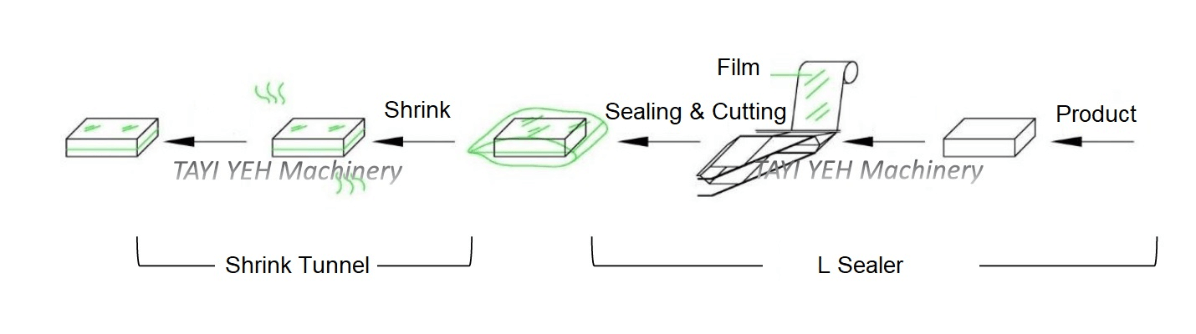

- Please refer shrink tunnel according to product size for shrinking application.

- 5-6kg/cm2 filter air is self-prepared by buyer.

| Model | TY-7315 | ||

|---|---|---|---|

| Machine(mm) L x W x H |

2400 x 1130 x 1650mm | ||

| Package Range(mm) L x W x H |

L:100-450mm W:50-300mm H:5-150mm |

||

| Speed | 1-45 packs/min. | ||

| Air consumption | 280L/min. | ||

| Power supply | 220V/60Hz/1ph | ||

| Power consumption | 2.6KW | ||

| Optional Device: Extended belt(for small product)、adjustable sealing line position、stainless steel frame、safety protection guard…etc., other requirement available upon request. |

|||

| *Other package sizes & power supply available upon request. *Package speed will differ from product size, film, and operator. *One option for max. L, W or H for package. |

|||

TY-7315 Machine Feature:

- Servo Motor control: Infeed belt, outfeed belt & film pulling.

- Sealing jaw opening height adjustable.

- Motor with soft start function for nice product sealing.

- Adjustable operation speed.

- Auto Film collection with sensor controlled.

- Efficient package capacity with close filling mode(non space between each product).

- Apply Mitsubishi PLC controller for stable operation performance.

- Apply Omron timer for control sealing & cutting time.

- Individual pin roller, adjustable pin position & amount.

- Adjustable film feeding tension.

- Panasonic sensors to control product entry position.

- Cutting blade made by 1 piece with long time operation durability.

- Temp. controller with PID function and driven by SSR for stable heating performance.

- Auto abnormal warning on sealing & cutting set.

- Infeed conveyor apply with roller for smooth operation.

- Directly adjustment on product entry width without hand tool.

- Rubber roller for tight film holding and pulling by timing belt.

- CE model available.

- Please refer shrink tunnel according to product size for shrinking application.

- 5-6kg/cm2 filter air is self-prepared by buyer.