Automatic Shrink Bundler - For Tray Package

SA-117 / SA-117-V

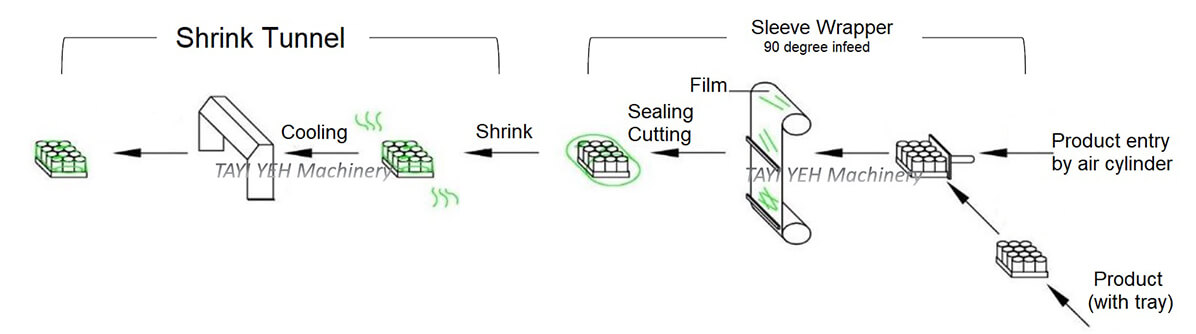

- SA-117: 90° infeed direction with air cylinder to push product.

- SA-117-V: vertical filling the products, min. product weight:2kg.

- Suitable for products with tray, such as: can、tin、bottle、tetra pak…etc., bundler package.

- Conveyor with guiding plates at 2 side for product entry.

- Attach air flush to cool sealing in a short time for tight strength.

- Equip with product entry sensor for smooth packaging process.

- Apply Mitsubishi PLC controller for stable operation performance.

- Sealing & cutting time adjustable through Omron timer.

- Temp. controller with PID function and driven by SSR for stable heating performance.

- Cutting blade made by 1piece for long time operation durability.

- Sealing & cutting with abnormal warning function.

- Outfeed conveyor auto delivery product out after wrapping.

- Customized machine with package processing design is available upon request.

- Please refer shrink tunnel according to product size for shrinking application.

- 5-6kg/cm2 filter air is provided by buyer.

| Model | SA-117 | SA-117-V | |

|---|---|---|---|

| Package Mode | 90° infeed with air cylinder | Vertical infeed (min.2 kg for package) |

|

| Machine L x W x H |

1710 x 2430 x 1710mm | 1830 x 1630 x 1710mm | |

| Package Range L x W x H |

L:100-300mm W:200-350mm H:50-170mm |

L:200-350mm W:200-330mm H:50-170mm |

|

| Film Material | PE | ||

| Speed | 1-16 pack/min | ||

| Power | 220V/380V/415V(upon request) | ||

| Power consumption | 2KW | 2KW | |

| Air consumption | 420L/min | 300L/min | |

| *Other package size available upon request. *Package speed will be differ from product size, film and operator. |

|||

- SA-117: 90° infeed direction with air cylinder to push product.

- SA-117-V: vertical filling the products, min. product weight:2kg.

- Suitable for products with tray, such as: can、tin、bottle、tetra pak…etc., bundler package.

- Conveyor with guiding plates at 2 side for product entry.

- Attach air flush to cool sealing in a short time for tight strength.

- Equip with product entry sensor for smooth packaging process.

- Apply Mitsubishi PLC controller for stable operation performance.

- Sealing & cutting time adjustable through Omron timer.

- Temp. controller with PID function and driven by SSR for stable heating performance.

- Cutting blade made by 1piece for long time operation durability.

- Sealing & cutting with abnormal warning function.

- Outfeed conveyor auto delivery product out after wrapping.

- Customized machine with package processing design is available upon request.

- Please refer shrink tunnel according to product size for shrinking application.

- 5-6kg/cm2 filter air is provided by buyer.