Automatic Sleeve Wrapper - For Bottles

SA-106-1 / SA-106-2

- Suitable for round shape products, such as: can、tin、bottle…etc., non-tray product.

- Machine combine seal & shrink functions for completed package.

- Infeed belt with product swing & alignment function.

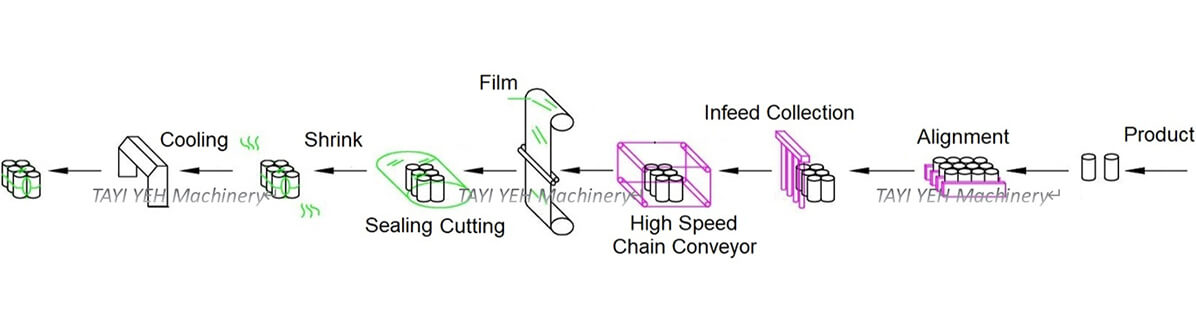

- Package process: product alignment →film wrapping→sealing & cutting → outfeed conveyor → shrink tunnel → package completed.

- Suitable for PE film package.

- Enable to change product alignment mode according to product.

- Fixed device on the top of product, ensure no movement while sealing & cutting.

- Adjustable product delivery speed、pushing timing、positioning、sealing timing…etc.

- Attach air flush to cool sealing in a short time for good strength.

- Equip product entry sensor for smooth filling process.

- Mitsubishi PLC controller.

- Temp. controller with PID function and driven by SSR for stable heating performance.

- Cutting blade made by one piece for long time operation stability.

- Auto delivery product into shrink tunnel after wrapping.

- Shrink temp. & speed are adjustable.

- Cooling fan in the rare of tunnel.

- Inner tunnel related heating parts are mainly made by stainless steel.

- 5-6kg/cm2 filter is provided by buyer.

| Model | SA-106-1(Single Line) | SA-106-1(Double Line) | |

|---|---|---|---|

| Machine | L 5170 x W1450 x H 2050mm | L 5170 x W 2350 x H 2050mm | |

| Package Range | L 360 x W240 x H180mm | Customized | |

| Speed | 1-22 pack /min | 1-44 pack/min | |

| Power | 220V/380V/415V(upon request) | ||

| Power consumption | 25KW | 50KW | |

| Air consumption | 380L/min | 760L/min | |

| *Package speed will be differ from product size, shape, film and operator. | |||

- Suitable for round shape products, such as: can、tin、bottle…etc., non-tray product.

- Machine combine seal & shrink functions for completed package.

- Infeed belt with product swing & alignment function.

- Package process: product alignment →film wrapping→sealing & cutting → outfeed conveyor → shrink tunnel → package completed.

- Suitable for PE film package.

- Enable to change product alignment mode according to product.

- Fixed device on the top of product, ensure no movement while sealing & cutting.

- Adjustable product delivery speed、pushing timing、positioning、sealing timing…etc.

- Attach air flush to cool sealing in a short time for good strength.

- Equip product entry sensor for smooth filling process.

- Mitsubishi PLC controller.

- Temp. controller with PID function and driven by SSR for stable heating performance.

- Cutting blade made by one piece for long time operation stability.

- Auto delivery product into shrink tunnel after wrapping.

- Shrink temp. & speed are adjustable.

- Cooling fan in the rare of tunnel.

- Inner tunnel related heating parts are mainly made by stainless steel.

- 5-6kg/cm2 filter is provided by buyer.